How SewPERCOAT TECHNOLOGY IS TRANSFORMING INFRASTRUCTURE

Manholes are vital components of urban infrastructure, providing essential access to underground utility systems like sewage, stormwater, and electrical networks. Over time, however, these critical structures can deteriorate due to environmental factors, heavy traffic, and general wear. When manholes begin to fail, it can lead to costly repairs, safety hazards, and disruptions. To address these challenges efficiently and affordably, modern technologies are essential. One such innovation is SewperCoat, a cutting-edge solution that has transformed the way manholes are repaired. At DRC Construction, we utilize SewperCoat technology to restore and extend the life of manholes, ensuring long-term durability and safety.

What is SewperCoat?

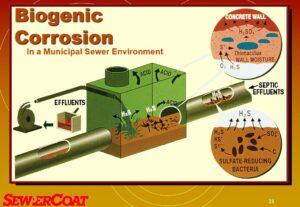

SewperCoat is a highly effective, trenchless technology designed for the repair and rehabilitation of manholes. This advanced spray-applied coating system is used to line the interior of manholes, protecting them from water infiltration, corrosion, and structural deterioration. SewperCoat is applied to the existing manhole structure without the need for costly excavation or replacement, making it a more efficient and cost-effective solution compared to traditional methods.

SewperCoat’s seamless, corrosion-resistant coating creates a long-lasting barrier that restores manholes’ functionality and extends their lifespan. It is particularly effective for concrete, brick, or masonry manholes that are exposed to harsh conditions, including sewage systems and stormwater infrastructure.

Why SewperCoat is the Go-To Solution for Manhole Repair

- Cost-Effective Repairs Traditional manhole repair methods typically involve extensive excavation, demolition, and rebuilding, which can be time-consuming and expensive. SewperCoat, on the other hand, provides an affordable alternative by eliminating the need for disruptive digging and replacing damaged sections. The coating system bonds directly to the existing structure, reducing both material and labor costs.

- Speed and Efficiency The SewperCoat application process is fast, often taking just a single day to complete. This significantly reduces downtime and minimizes disruptions to traffic or surrounding infrastructure. For cities and municipalities with busy streets and critical utility systems, this speed is a key advantage.

- Long-Term Durability SewperCoat’s durability is one of its most significant benefits. The high-performance coating is resistant to corrosion, water infiltration, chemicals, and abrasion, ensuring a long-lasting solution that reduces the need for frequent repairs. This makes SewperCoat ideal for manholes in challenging environments, such as those found in sewage systems or flood-prone areas.

- Seamless Protection Unlike traditional patching methods, SewperCoat provides a smooth, uniform lining that covers the entire manhole surface. This seamless application eliminates potential weak spots and ensures that water or debris cannot penetrate the repair. The result is a more reliable and efficient solution that provides comprehensive protection.

- Enhanced Safety Manholes in poor condition can be hazardous to both workers and the public. SewperCoat helps restore the structural integrity of these critical components, reducing the risk of collapse or other safety hazards. Furthermore, the application process is safe, requiring minimal exposure to harmful chemicals or dangerous working conditions.

- Environmentally Friendly The trenchless nature of SewperCoat minimizes the environmental impact of manhole repairs. There’s no need for extensive excavation or the removal of old materials, which helps preserve surrounding areas and reduces waste. Additionally, the materials used in the coating are eco-friendly, making SewperCoat a sustainable option for infrastructure maintenance.

The SewperCoat Repair Process

The SewperCoat application process is a straightforward and efficient series of steps:

- Inspection and Cleaning: The first step is a thorough inspection of the manhole to assess the extent of damage. Once the condition is evaluated, the manhole is cleaned to remove dirt, grease, and any loose material that might hinder the coating’s adhesion.

- Surface Preparation: The next step involves preparing the manhole surface through abrasive blasting or hydroblasting to ensure the coating adheres properly. This step is crucial for achieving optimal bonding between the coating and the existing structure.

- Application of SewperCoat: The SewperCoat material is then applied to the manhole surface in a series of layers. This spray-applied coating forms a smooth, seamless liner that protects against corrosion and water infiltration.

- Curing and Inspection: After the coating is applied, it is allowed to cure and harden. Once the curing process is complete, the manhole is inspected to ensure the repair meets the necessary standards of quality and safety.

- Recommissioning: The manhole is then put back into service, providing a durable and effective solution for infrastructure management.

Applications of SewperCoat Technology

SewperCoat is an ideal solution for a variety of manhole repair applications, including:

- Sewage System Manholes: SewperCoat is particularly effective in sewage systems, where manholes are exposed to harsh chemicals and wastewater. The coating protects the manhole from corrosion and prevents water infiltration, extending the life of the infrastructure.

- Stormwater System Manholes: Stormwater manholes can suffer from erosion and contamination due to rainwater and debris. SewperCoat provides a reliable solution that shields the manhole from the damaging effects of environmental exposure.

- Flooded or Deteriorating Manholes: Manholes that have experienced flooding, erosion, or significant physical damage can be rehabilitated using SewperCoat, avoiding the need for costly and disruptive full replacements.

- Industrial Zone Manholes: Manholes located in industrial areas are often subject to higher levels of stress, such as exposure to chemicals and heavy traffic. SewperCoat’s durable coating ensures that these manholes remain safe and functional.

Why Choose DRC Construction for SewperCoat Manhole Repairs?

At DRC Construction, we are committed to providing high-quality, innovative solutions for manhole rehabilitation and infrastructure repair. We have incorporated SewperCoat technology into our suite of services to offer municipalities and utility companies a fast, cost-effective, and reliable solution to manhole issues. Our team of trained experts ensures that every project is completed with precision and care, delivering results that exceed expectations.

We are proud to serve the Denver Area, including Sedalia and surrounding regions. With years of experience in infrastructure repair, DRC Construction is your trusted partner in manhole rehabilitation and other trenchless technology solutions.

By utilizing SewperCoat, we help municipalities and utility companies keep their infrastructure in peak condition, improving safety, efficiency, and long-term sustainability. For more information on how SewperCoat can benefit your infrastructure, contact us at DRC Construction (303) 688-2166, and let us provide you with a comprehensive and lasting solution for your manhole repair needs.